See how 30 Danone factories worldwide across all divisions use Poka in support of Danone’s Digital Manufacturing Acceleration Plan.

Poka is the first web and mobile application designed to give workers the ability to learn continuously, collaborate to solve problems and share important updates in real-time, from the factory floor.

75%

Less time to set up and track skills

2x

Increase in defect handling process

Danone has been a trailblazer with more than 30,000 Poka form completions to date, moving nearly 300 processes off paper and saving Danone 40,000 pieces of paper per year.

This video, featuring Magdalena Soból, The Digital Project Leader at Danone, showcases best practices for driving forms adoption which helped Danone Bierun win the Paperless Factory Award in 2021.

.png?width=856&quality=high)

Danone Auckland completed 491 Quality assessments in just one week by leveraging Poka’s digital skills management and training capability.

A lot of work has been done to be at the HACCP Excellence Level working on the tool POKA. The deployment of this tool in Auckland is a success allowing to have clear communication, training and assessment on Food Safety Topics including the CCP/oPRP Management

FSI Auditor

.png?width=1043&quality=high)

Danone Zoetermeer uses Poka to support continuous learning for role-specific skills.

New operators don’t need to learn everything during onboarding because now we are confident they can find it when they need it.

Learning & Development Manager, Danone

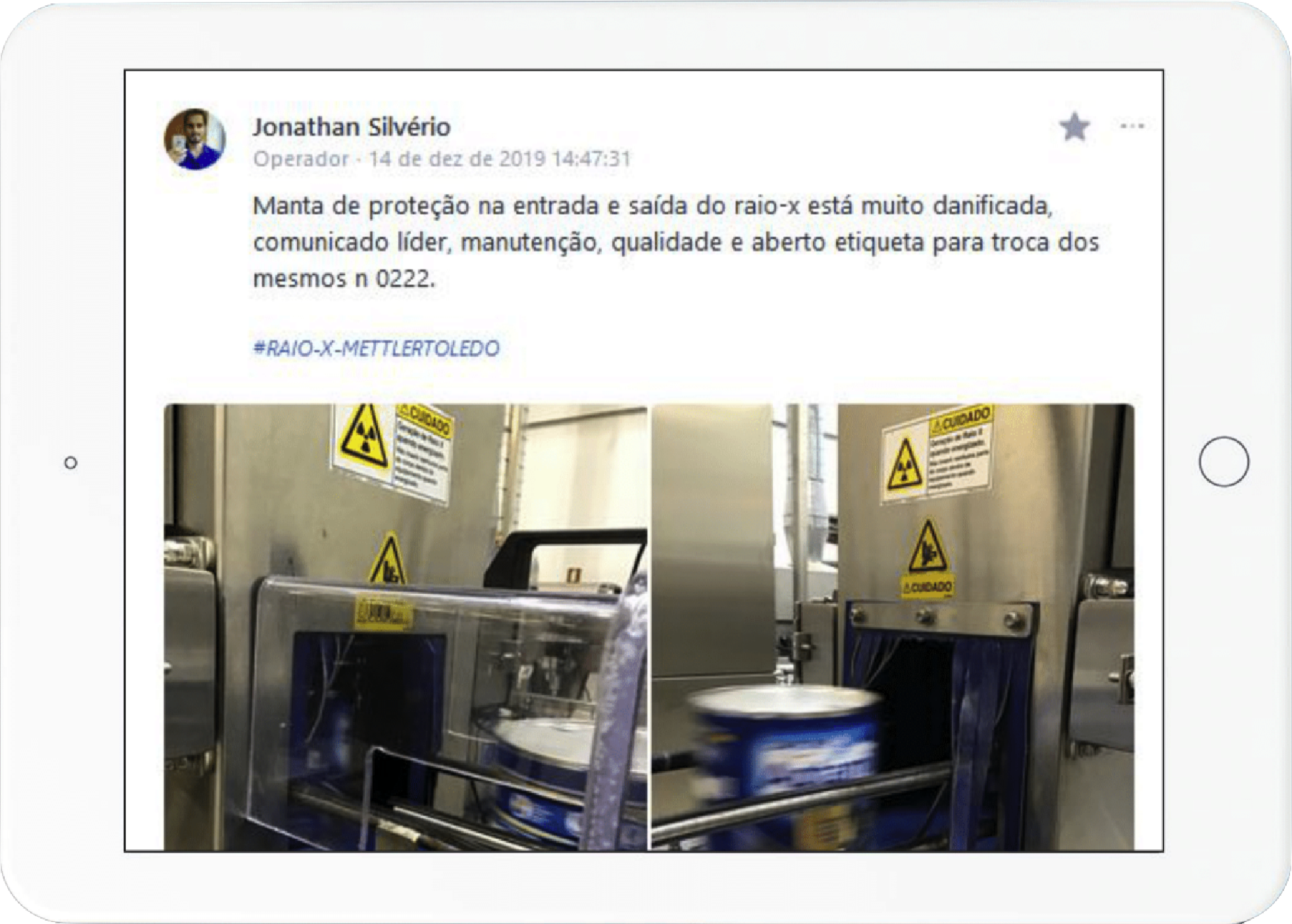

Danone Pocos and Opole use Poka’s issues management and communication capabilities to accelerate time to resolution and improve visibility and escalation of issues.

We can now go to the iPad and fill Poka forms during Gemba walks and move from whiteboard signatures to digital signatures for CIL checklists. We’ve saved the equivalent of 141 hours per year by going paperless!

The Digital Project Leader at Danone

Join us for our 3-day user conference Poka Empower 2022: Accelerating Impact in September 13-15!